They serve a critical function and design depends on various factors.

Function of sag rod in roof truss.

More sag rods means more support along the span of the purlin which helps greatly in slenderness and deflection.

Here are some of the benefits of installing a roof truss.

Without roof buildings would be exposed to all kinds of elements rendering them completely useless.

Key in a roof hasp a rod for preventing the sagging of an open web steel joist that is used as a purlin with its depth at right angles to a roof slope.

However the weight of a ceiling affixed to rafter ties of any dimension can cause ceiling sagging unless the lumber is also sized to support the vertical load or weight of the ceiling.

These are round bar threaded at their ends parallel to the roof slope and secured to the purlin webs with nuts often at their mid points or one third points of their span.

When ceiling joists run perpendicular to the rafters inspectors may find rafter ties installed above ceiling joists as framing members every 4 feet running above the ceiling joists.

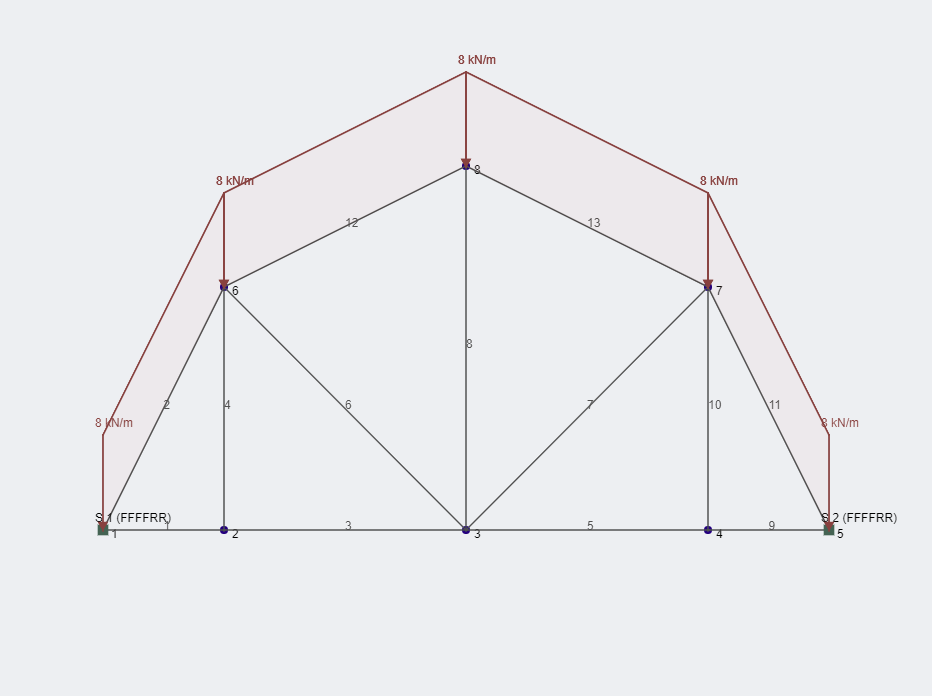

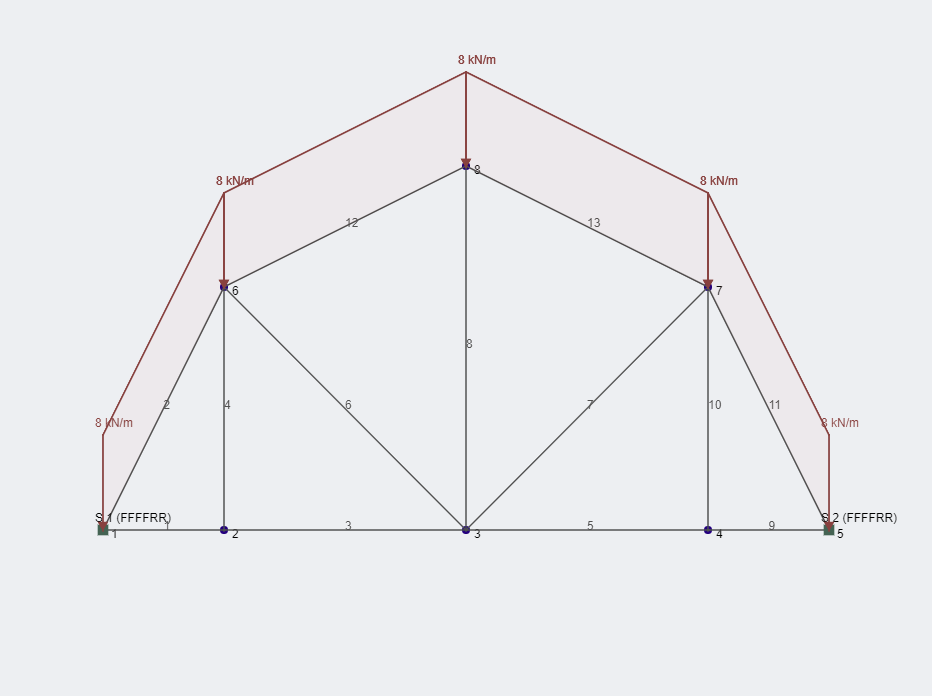

Design of purlins sag rods and tie rods updated design of purlins sag rods and tie rods stato di avanzamento progress report ce 514l unified compression test.

A rafter tie forms the bottom chord of a simple triangular roof truss.

In a roof truss design the additional web members of the truss help resist sagging of the bottom cord and add rigidity to the truss structure.

A roof truss is considered the most important key component in engineering system in a building.

Usually trusses are put 24 inches apart.

To hold them up until the decking of the roof is placed on top a 12 foot 1 inch by 4 inch piece of lumber is used.

Sag rods are usually furnished to transmit the gravity load of girts to a supporting member.

Compute the corresponding flexural moments for no sag rod layout middle sag rod layout and along thirds sag rod layout.

The ultimate moment for no sag rod layout is computed the same way as simple supported.

This is used to decrease the stresses caused through biaxial bending of the purlins.

Typical sag rods are 5 8 in.

In diameter with lines spaced approximately six to right feet apart.

A sagging ridge is one indication that the roof structure may lack adequate rafter ties.