Rubber cal is america s premier source for gym flooring neoprene rubber kitchen mats anti slip mats epdm rubber garage floor covering commercial entrance mats and more.

Epdm rubber manufacturing process.

Many of the rubber manufacturing facilities in the united states produce pneumatic tires for automobile trucks airplanes and farm machinery.

Epdm rubber ethylene propylene diene monomer rubber is a type of synthetic rubber that is used in many applications.

Harvesting latex from rubber trees starts with scoring or cutting into the bark of the tree.

In addition other products that work well with epdm are washers die cut rubber gaskets isolators belts intake hoses weather stripping water.

4 12 manufacture of rubber products.

The natural rubber manufacturing process begins with harvesting latex from rubber trees.

Epdm navigates these issues thanks to its synthetic.

They are also not suited to being manipulated or adapted.

Epdm granules are the materials in high demand.

The epdm manufacturing process conventional natural rubber materials do not have the characteristics to make them suitable for roofing.

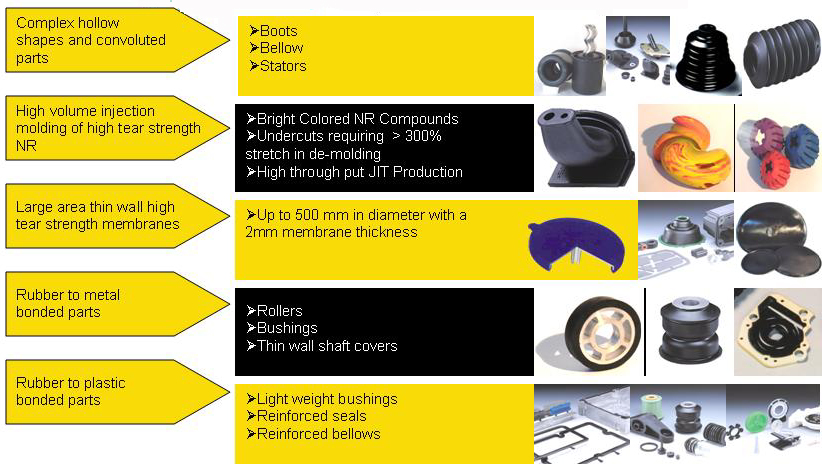

Epdm lends itself to working well with compression transfer and injection molding processes as well as the extrusion process for products like rubber hoses electrical cables tubing and seals.

Epdm is an m class rubber under astm standard d 1418.

They are used in many industries for different purposes.

Our company offers a variety of colored epdm granules fro various flooring purposes.

Epdm is made from ethylene propylene and a diene comonomer that enables.

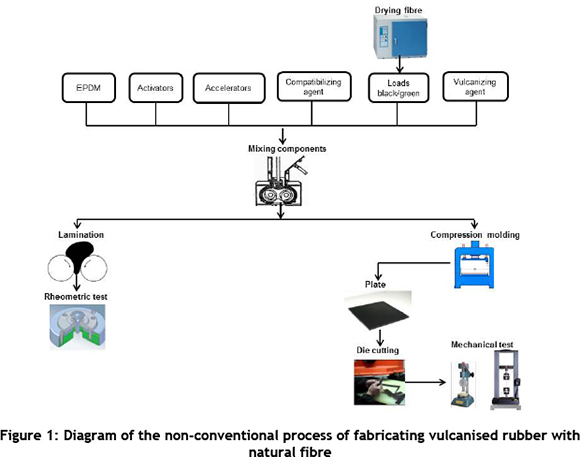

Materials and manufacturing processes summary this paper will review the raw materials used in the production of epdm based compounds used to manufacture single ply membranes for the commercial roofing industry.

They are inelastic prone to expansion and have poor tensile strength and heat resistance.

However many rubber manufacturing facilities produce other engineered rubber products.

Latex flows into a cup attached to the bottom of the cut in the tree.

The latex material from many trees is accumulated in large tanks.

The m class comprises elastomers having a saturated chain of the polyethylene type the m deriving from the more correct term polymethylene.

4 12 1 general process description1.